INCX software was born out of the continuous and close collaboration between INCIMAR and the customers of our Numerical Control Engravers.

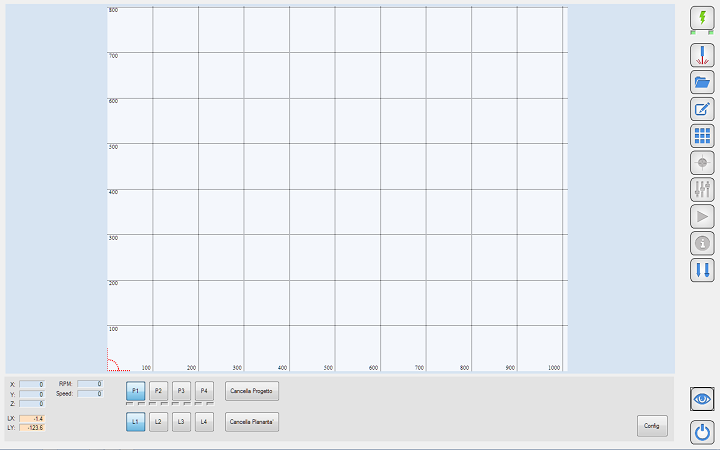

A simple interface, a straightforward machining process, and a set of options for machining optimization that is found only in our own production make INCX extremely easy to learn and to use already after a minimum course of less than two hours.

Along with INCX, our fast composer also makes a difference when you need to be productive.

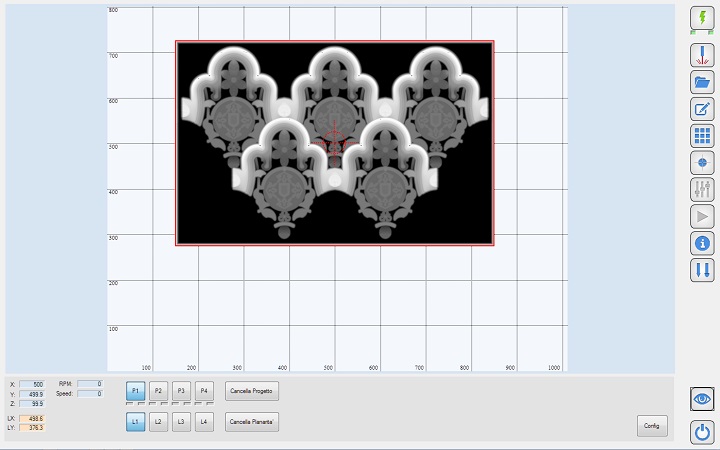

The fast loading and placement of components makes it possible to compose a slab in a matter of minutes.

INCIMAR alphabets attached to the composer can be engraved in any size, making it easy even to complete an old plate by adding new names and dates.

For each element, you can easily change its size and rotation, as well as its depth.

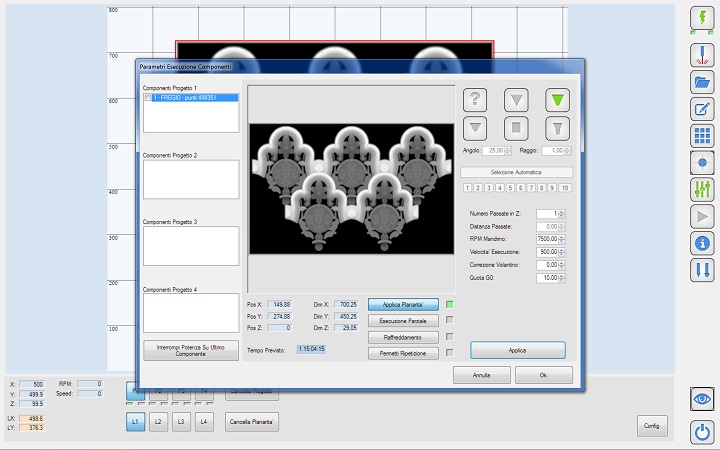

An excellent engraving result can only be obtained if the Engraver is able to follow the surface of the plate, whether it is linear or book-shaped, for example.

INCX makes it easy to scan the plate being processed and likewise to scan a 3D model (such as a bas-relief) and then be able to edit and engrave it.

INCX has a wide range of configuration and execution options, not the least of which is managing engraving in multiple passes without changing anything about your design.

For example, if you need to engrave a very deep bas-relief, you can set it to run in two passes, and automatically the software will handle the design change.